|

| LEADER OF ELECTROLYSIS TECHNOLOGY |

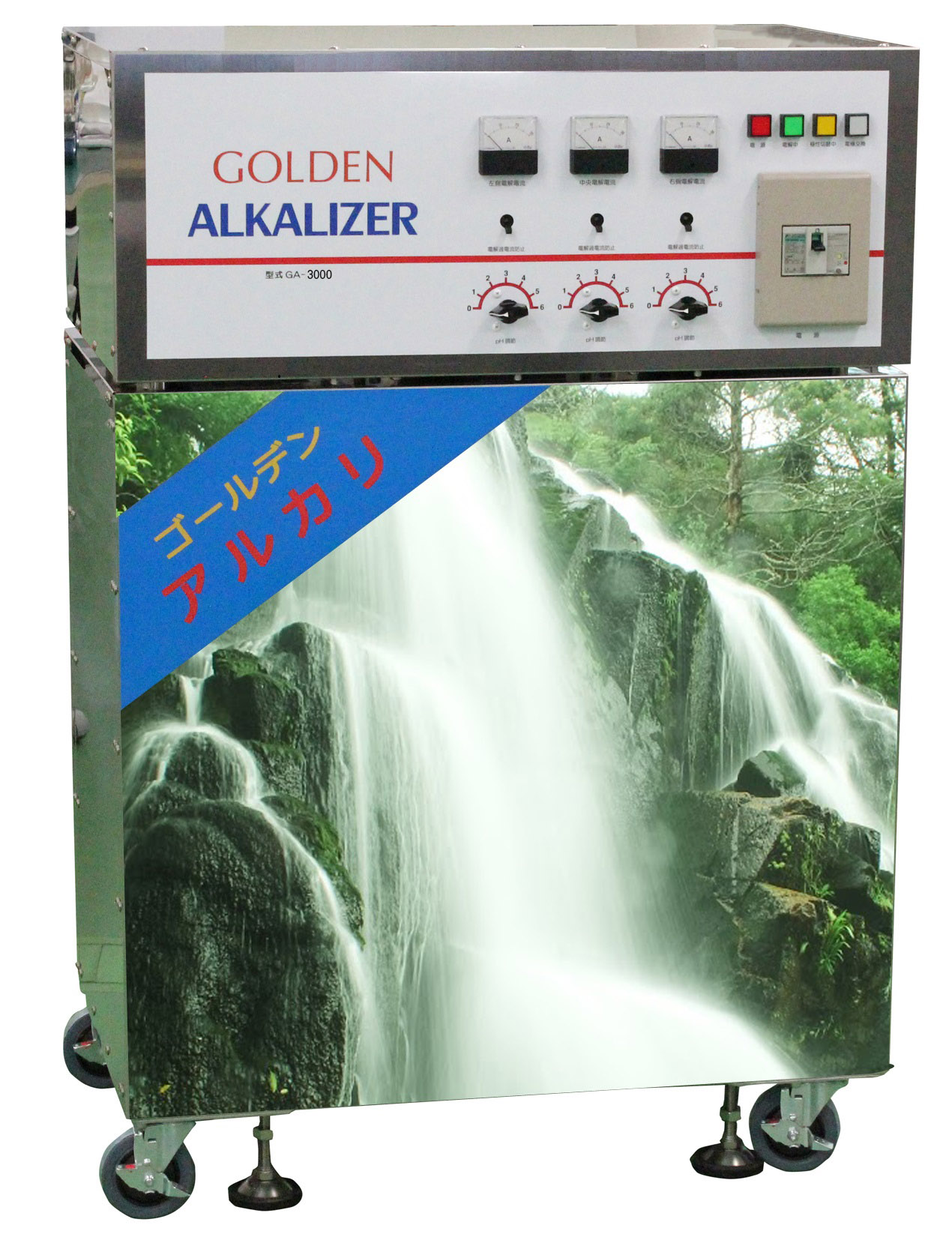

Machinery and Specifications

GA-3000

|

Name |

WATER ELECTROLYSIS APPARATUS |

|

Machine Number |

GA-3000 |

|

Power supply |

AC220V (3-phase) 50A 18KW |

|

Weight |

Whole unit: about 250kg |

|

Dimensions |

Whole Unit:W843×D640×H1,240 (mm) Power unit: W845×D466×H355 (mm) |

| Electrolysis unit: W887×D523×H864 (mm) | |

|

Water generation (input water pressure: |

Alkaline Ionized water: about 3,000L/hr (see input water volume) |

|

Acidic Ionized water: about 1,000L/hr (see input water volume) |

|

|

pH |

Alkaline Ionized water: 7~10; Acidic electrolytic water: 4~7 (Depend on the feed water) |

Product Original: made in Japan.

Machine Specification subject to change without prior notice

The New Functions of GA-3000/GA-3002 Industrial Electrolysis Water Machines

The New Functions of GA-3000/GA-3002

Industrial Electrolysis Water Machines

According to Chairman of OKAZAKI, the designer of OMT (OKAZAKI MANUFACTURE TECHNOLOGY) who has remodeled the GA machines from the old model of machine and the GA new machine has equipment with the functions or devices as follows:

| √ | PLC System Installed (NEW) | Compared the relay cord of old model, The GA machine has the PLC (computer program), which able recording the machine operation data and adjusting the running mode which fit the feed water quality. |

|---|---|---|

| √ | Supreme high electrolysis efficiency | The electrolysis efficiency is some twice stronger than the old model (theory value) which easier to obtain the high pH of water expected. |

| √ | New Reverse Wash System-PATENTED (NEW) | For avoid acidic water leakage into alkaline ionized water in old model, the GA new model designated with new special reverse washing system. The acidic ionized water will not mix into alkaline ionized water tank for ensure the quality of alkaline ion aquatic productions. |

| √ | Auto Water Pressure Protect System (NEW) | The GA machine has equipped with automatic water pressure protection system, if the water pressure (Below 0.5Kg/cm) is abnormal then machine will auto shut off so that avoid caused malfunctions or transformer burn down. |

| √ | Over current automatic protection device | The machine has equipped with automatic over-current protection device to prevent over-current, damage to the machine. Seven electrolysis switcher (Stage 0 - 6 section), may adjust electrolytic current to fit water quality, producing the desired PH value of alkaline ionized water. |

| √ | Chambers Exchange Alert (NEW) | The GA equipped the new chambers exchange Alert Lamp, Upon the cell life is due the alert lamp will light up auto so that customer can be preparing exchanging the electrolysis chambers on time for ensure production quality. |

| √ | Protection device for electricity polarity (NEW) | GA machine has the protection device for electricity polarity and the GA machine installed 9 electricity connectors which customers may select the suitable connectors to fit the feed water quality so that obtain the pH of alkaline ionized water desired. |

| √ | Green water-saving technology | GA machine has green water saving technology which output of alkaline ionized water about 3 tons (3/4), acidic ionized water about 1 ton (1/4). More saving water than ordinary equipment. |

| √ | Water Proof Designs (NEW) | GA machines has the design of chambers leakage prevention so that prevent from any water leakage or malfunctions caused. |

| √ | Increase machine inner space | Simplify the machine internal lines & piping system, increase machine inner space for service jobs. |

For detail Please contact us:

Super Aqua International Co Ltd.,

superaqua168@gmail.com

English

English  繁體中文

繁體中文  简体中文

简体中文